Revolutionizing Precision Manufacturing: The Power of 5 Axis Laser Cutting

5 axis laser cutting represents a significant advancement in the field of precision manufacturing. This technology offers unparalleled flexibility and accuracy for a wide range of materials and industries. In this comprehensive article, we will explore what 5 axis laser cutting is, its numerous benefits, applications, and its impact on modern manufacturing.

What is 5 Axis Laser Cutting?

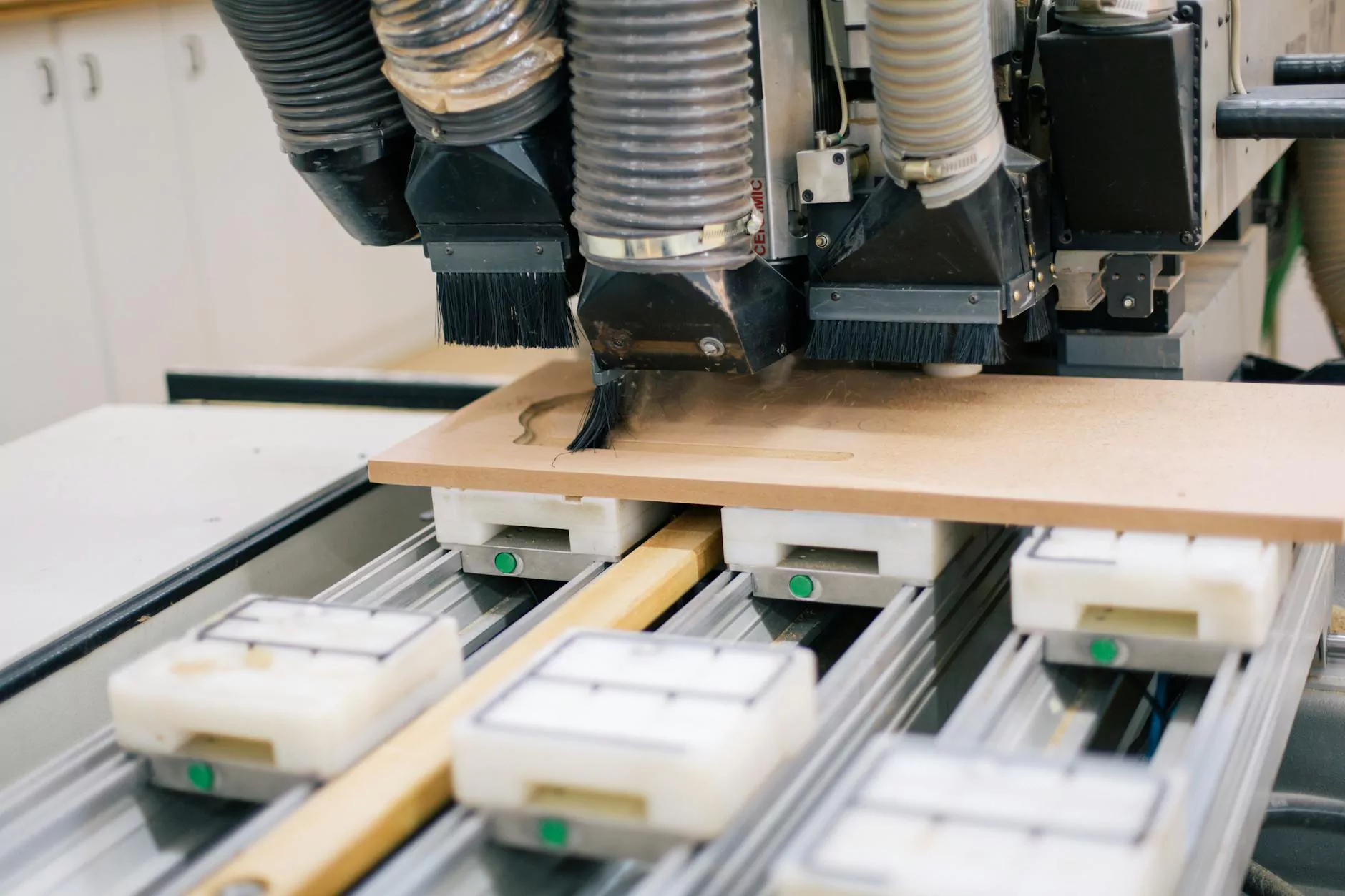

In laser cutting, the term "5 axis" refers to the capability of the laser machine to move and operate on five different axes simultaneously. Traditional laser cutting typically operates on two or three axes, limiting the complexity of the shapes that can be produced. However, with 5 axis laser cutting, the machine can maneuver in a more nuanced manner, allowing for intricate design work to be executed with accuracy.

Understanding the Axes

The axes in 5 axis laser cutting are as follows:

- X-axis: Horizontal movement left or right.

- Y-axis: Vertical movement up or down.

- Z-axis: Depth movement, allowing the laser to cut through different material thicknesses.

- A-axis: Rotation along the X-axis, enabling bevel cuts.

- B-axis: Rotation along the Y-axis, adding more dimensions to the cutting capabilities.

Advantages of 5 Axis Laser Cutting

There are several benefits to utilizing 5 axis laser cutting technology in manufacturing and design processes:

1. Enhanced Precision

One of the primary benefits of 5 axis laser cutting is its remarkable precision. This capability allows for intricate designs and complex geometries to be produced with minimal tolerances. The movement along multiple axes reduces the risk of errors and ensures that the final product closely matches the design specifications.

2. Increased Efficiency

Traditional laser cutting often requires multiple setups and adjustments for complex cuts. With 5 axis laser cutting, the ability to make different cuts without repositioning the material streamlines the process significantly. This efficiency leads to faster production times and reduced labor costs, making it financially advantageous for businesses.

3. Versatility in Material Processing

5 axis laser cutting can handle a variety of materials, including metals, plastics, and composites. This versatility is especially beneficial in industries such as aerospace, automotive, and medical device manufacturing, where different materials are frequently used and precise cuts are necessary.

4. Improved Surface Finish

Another advantage of utilizing 5 axis technology is the superior surface finish of the cut edges. The laser's precision results in cleaner cuts with minimal post-processing required, which can save time and resources.

5. Design Freedom

With the capabilities of 5 axis laser cutting, designers have greater freedom to create complex shapes that were previously impossible or impractical to manufacture. This expanded design potential can lead to innovative products and solutions.

Applications of 5 Axis Laser Cutting

The applications of 5 axis laser cutting are diverse, spanning multiple industries. Below, we highlight some of the key sectors benefiting from this advanced technology:

Aerospace Industry

In aerospace manufacturing, precision and weight reduction are critical factors. 5 axis laser cutting allows for the fabrication of lightweight structural components and intricate parts with precise tolerances, ensuring aircraft efficiency and safety.

Automotive Industry

The automotive sector utilizes this technology to produce complex parts such as brackets, housings, and heat exchangers. The ability to create intricate cut patterns while maintaining strength and durability is essential in today’s competitive automotive landscape.

Medical Devices

Manufacturers of medical devices rely on 5 axis laser cutting for the production of components that require stringent quality control and precision. Surgical instruments, implants, and other medical solutions benefit greatly from this technology.

Art and Design

Artists and designers are exploring laser cutting for creating sculptures, architectural elements, and custom pieces. The ability to craft unique designs quickly and with precision opens new creative avenues.

Electronics Manufacturing

In electronics, 5 axis laser cutting is used for cutting circuit boards and creating enclosures with intricate designs. The precision of laser cutting ensures that electronic components are accurately placed and housed, enhancing device functionality and reliability.

Choosing the Right 5 Axis Laser Cutting Machine

When selecting a 5 axis laser cutting machine, several factors should be taken into consideration to ensure that the equipment meets your business needs:

1. Power and Speed

The power of the laser determines its capability to cut through different material thicknesses efficiently. Additionally, consider the cutting speed and how it aligns with your production requirements.

2. Material Compatibility

Ensure that the chosen machine can handle the materials you plan to work with. Different lasers are suited for specific materials, so understanding your material requirements is crucial.

3. Software Compatibility

A user-friendly interface and software compatibility are essential for seamless integration into your design and production workflow. Look for machines with intuitive controls and robust software support.

4. Maintenance and Support

Consider the availability of maintenance services and customer support. Investing in a machine that is easy to maintain and backed by excellent customer support will enhance your operational efficiency.

5. Cost versus Value

While initial costs may vary, focus on the overall value the machine will provide. A higher upfront cost may be justified by enhanced capabilities, reliability, and efficiency in production.

Conclusion: The Future of Manufacturing with 5 Axis Laser Cutting

The advent of 5 axis laser cutting technology redefines the landscape of manufacturing, driving innovation and productivity across various industries. Its unmatched precision, efficiency, and versatility position it as a vital tool for businesses looking to maintain a competitive edge. As technology continues to evolve, we can expect even more advanced applications and improvements in 5 axis laser cutting, making it a cornerstone of modern manufacturing practices.

For businesses seeking to explore the capabilities of advanced laser cutting, transitioning to 5 axis systems may unlock new potential and efficiencies. Discover more about 5 axis laser cutting machines and how you can leverage this technology for your manufacturing needs at roclas-laser.com.